VOLVO+ Development Story (2), low power design

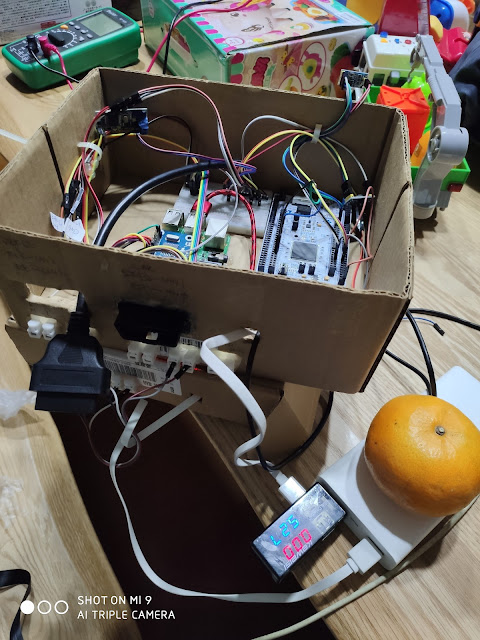

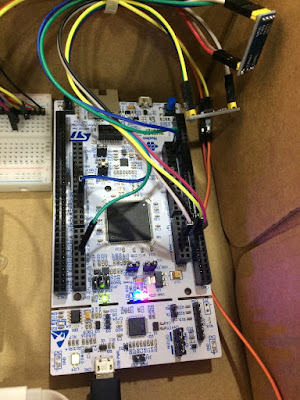

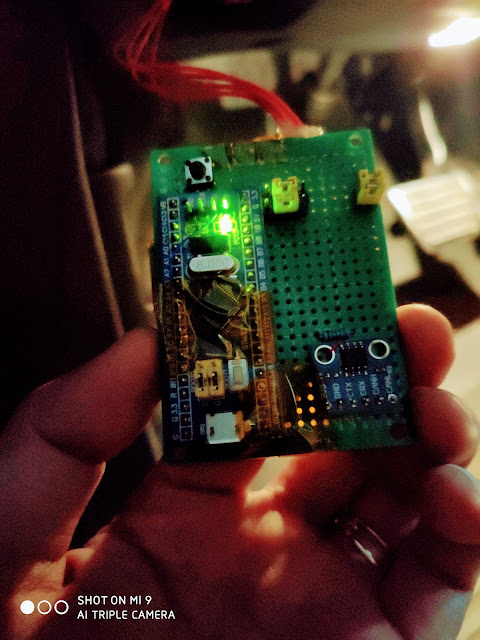

After the 1st prototype broken , I made several prototypes again. I'm not good at soldering so I re-do the prototypes several times to get a working board. To make VOLVO+ become a real product, I have to do something difficult: low power mechanism VOLVO XC60 used AGM battery which costs ~300USD and many people complained the lifetime is only roughly 2 years. It means 150USD expense per year. The basic idea to make lead-acid battery healthy is simple: make the battery fully charged I don't want VOLVO+ kill my battery, so I shall design low power mechanism carefully As engine on, the VOLVO car's alternator can output >100A while VOLVO+ only drains 13mA, which is so small to neglect. As the engine-off, VOLVO+ keeps draining the battery as it's plugging to OBD2. So the real challenge is: how to minimize the standby power I defined a useful metric to measure low-power performance: how long does VOLVO+ standby power drains 1% battery. The longer time, the better low-power...