VOLVO+ Development Story (2), low power design

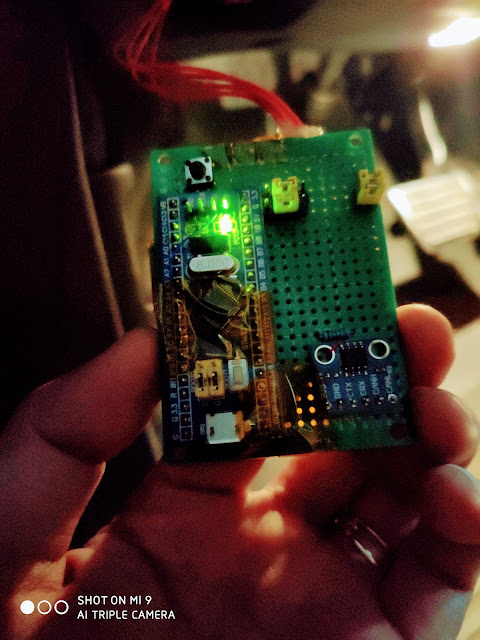

After the 1st prototype broken, I made several prototypes again. I'm not good at soldering so I re-do the prototypes several times to get a working board. To make VOLVO+ become a real product, I have to do something difficult: low power mechanism

VOLVO XC60 used AGM battery which costs ~300USD and many people complained the lifetime is only roughly 2 years. It means 150USD expense per year. The basic idea to make lead-acid battery healthy is simple: make the battery fully charged

I don't want VOLVO+ kill my battery, so I shall design low power mechanism carefully

As engine on, the VOLVO car's alternator can output >100A while VOLVO+ only drains 13mA, which is so small to neglect. As the engine-off, VOLVO+ keeps draining the battery as it's plugging to OBD2. So the real challenge is: how to minimize the standby power

I defined a useful metric to measure low-power performance: how long does VOLVO+ standby power drains 1% battery. The longer time, the better low-power performance. Picture below is my car's battery, EFB 70Ah. So 1% battery in this article is 70Ah * 1% = 0.7Ah

Static Power Consumption (2019/05)

With some engineering effort, I've reduced the standby power to 0.385mA. This means 1% battery can last 75days, or 2.5months. The self-discharge of lead-acid battery is 3% per month. The number is far below the self-charge, and that's sufficient low-power performance

0.7Ah = (0.385*0.001)A *24h*75.75days

Low Power Mechanism (obsoleted)

We designed the wake-up and sleep mechanism according to car's CAN bus behavior. In the picture below, the left column unit is seconds. As car is awaken, the packets appeared every 0.001 (1ms)

As MCU wakes up, it monitors the CAN bus for 10ms. The time should be sufficient to cover 5 packets. If receives any valid packets, then keeps waking up for 20 seconds

If not receiving any packets, it means the car is sleeping. To detect the CAN bus is alive, I set MCU wake-up period at 3 seconds. It's expected to be sufficient to capture any human operation

According to the parameters above (wake-up period=3000ms, wake-up-time=10ms), the weighted power consumption is 0.385mA

- 3000ms standby, 0.345mA

- 10ms normal operation, 12.430mA

- Weighted average (3000*0.345 + 10*12.430) / (3010) = 0.385mA = 385uA

Further analyze the standby power, the TI CAN transceiver is of ~95%

- TI CAN TRANSCEIVER, 370uA

- CPU, 3.2uA

- LDO, 15uA

TI had several CAN transceiver models. I planned to use SN65HVD231, whose standby power reduces to 0.04uA. After switching to this IC, 1% battery can last 4 years. The number is actually sort of meaningless if considering the lead-acid self-discharge at 3%/months

After designing proper low-power strategy, I'm willing to place VOLVO+ prototype on my car (I'm quite picky to low-power design)

Static Power Consumption (2019/10)

Final static power consumption is <30uA, which drains 1% battery in >2years. So the power consumption is no longer a problem now

Comments

Post a Comment